Shenzhen Honreal Technology Co.,Ltd

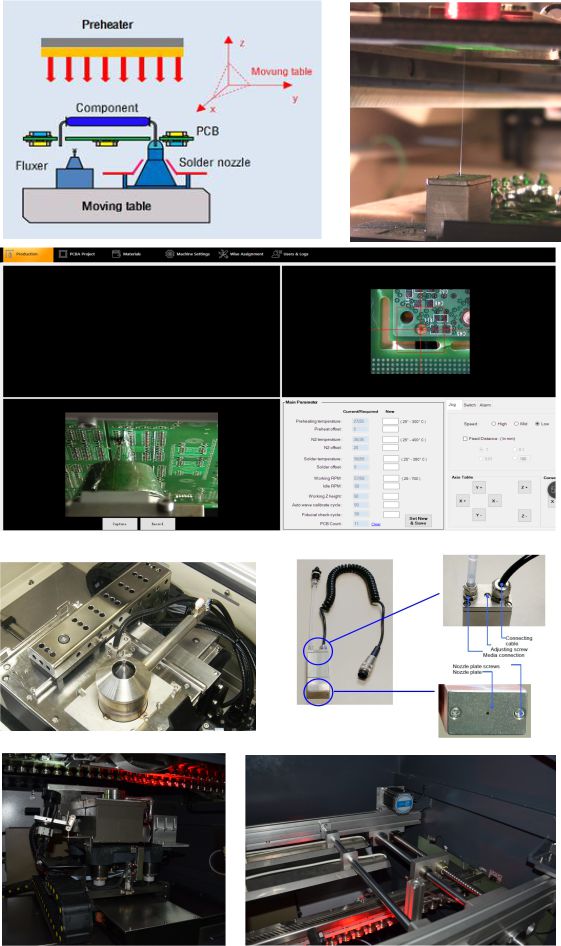

Shenzhen Honreal Technology Co. Ltd. is a leading R&D and

manufacturing company that specializes in providing various brands

of SMT pick and place machines and spare parts , reflow oven, wave

soldering machine,PCB handling equipment ect smt factory machines.

An enterprise that integrates , sales and service and provides

comprehensive solutions for SMT process technology. Our R&D

personnel often go directly to the customer's equipment use site to

understand the usage conditions of the equipment, seek the best

solutions, and continuously introduce updated and improved

products. Shenzhen Honreal helps you get efficient returns with the

lowest cost investment, and is the most ideal choice for SMT

factory users

The company has a technical engineering team with many years of

experience in technology development, process operation, and

technical services of SMT equipment. The company aims at stable

design concepts, advanced technical levels, rigorous manufacturing

processes, and reasonable sales prices. The company upholds the

belief that firmness and mediocre quality are incompatible, and

firmly believes that perfect quality lies in careful manufacturing.

For this reason, each of the company's equipment is equipped with a

detailed and rigorous production process and IPQC and FQC

processes, never letting go of every detail to ensure Product

stability and service life. The company's approach to employment is

to discover, tap, cultivate, and retain talents. Hongrun Technology

is small but ambitious, with heavy responsibilities and a long way

to go.