Why we use selective wave soldering machine?

Although some components can be soldered through the THT process,

some high-capacity and fine-pitch components are difficult to meet.

Therefore, the selective soldering machine has to be used.

The tin penetration of wave soldering machine can only reach 75%,

but the selective wave soldering machines with selective soldering

system can reach 100% penetration rate.

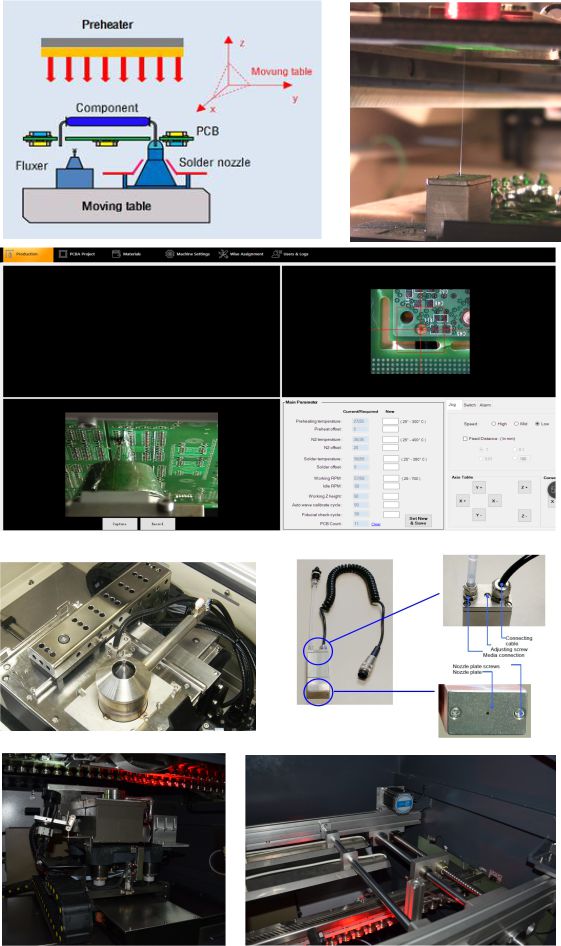

HRX-32 selective soldering machine combine with flux spray module,

preheating module, soldering module, integrated design, and free

expansion. The flux pray use the Point-to-point spraying, which can

save a lot of flux. The preheating use up hot air and bottom IR, It

can quickly evaporate the moisture of the flux and bring the PCB

board to a certain temperature, so that the PCB will not be

subjected to shock heating when it is in contact with the liquid

solder. The soldering module can be used single pot or dual pot

according to customer requirement, The electromagnetic pump ensures

extremely constant flow for precise and fine-tuned solder wave

heights. With top technology and modular design of HRX-32 selective

wave soldering machine, HRX-32 selective soldering machine meets

the highest demands for flexibility and throughput

Now selective soldering machine widely used automotive, medical,

military etc. industry, and HRX-32 selective wave soldering machine

will be your best choice.

SoftwarePart:

- All software system developed by company from India, with our

practical experience about selective soldering, base on Windows7

system, with good trace-ability.

- Use scanned picture as background for path programming, moving

speed, dwell time, empty move speed, Z height , wave height etc all

programmed for different solder site.

- Show solder process with live on camera.

- Critical parameters are totally under monitoring by PC software,

like temperature, speed, pressure etc.

- With auto wave height calibration function, to check & calibrate

wave’s height after every certain pcb, so to keep a very good

stability of wave.

- Can upgraded to be with Mark positioning function, to check PCB’s

mark point after every certain pcb, so to be reduce the pcb’s

position offset.

- About PCB’s menu in soldering machine, all information will be

stocked in one file. It will include PCB dimension and picture,

used flux type, solder type, solder nozzle type, solder

temperature, N2 temperature, motion path and each site’s related

wave height and Z height etc. When customer to solder same PCB,

they can get full information about how it’s done in history, also

easy for trace.

- With LOG function, provide 3 level to enter software with different

rights. Meanwhile, can record machine’s operation & alarm.

Technical Parameters:

Machine name | SEL-32 |

General |

dimension | L2860mm X W1650mm X H1650mm |

general power | 16kw |

consumption power | 4--8kw |

power supply | Single-phase 220V 50HZ |

net weight | 1500KG |

reuiqred air source | 3-5BAR |

required N2 flow and purity | 3 m³ /hour,purity>99.998% |

required exhausting | 600--1000CMB/H |

controlling & conveyor |

controlling | Industrial PC + PLC control |

conveyor width | 100-600MM |

conveyor type | Spray and preheating section chain rail transport, solder section

roller transport |

PCB conveyor direction | Left to right or Right left |

conveyor rail | Aluminum rail |

conveyor height | 900+/-30mm |

Motion table |

|

motion axis | X, Y, Z |

motion control | Closed-loop servo control |

position accuracy | + / - 0.05 mm |

flame | metal welding |

Flux management |

|

flux nozzle | Japan Lumina |

nozzle durability | stainless steel |

flux tank capacity | 1L |

alcohol tank capacity | 1L |

Preheat |

|

preheat method | hot air on the top,IR heater at bottom |

heater’s power | 6kw |

temperature range | 25--240c degree |

Solder pot |

|

standard pot number | 1PCS |

solder pot capacity | 13 kgs / solder pot |

solder temperature range | PID |

melting time | 30 Minutes |

max solder temperature | 350 C |

solder heater | 1.5kw/ solder pot |

Solder nozzle |

|

nozzle dim | customized |

material | high carbon alloy |

standard equipped nozzle | tandard equipped 5pcs(2.5mm/ 3.0mm/ 4.0mm/ 5.0mm/ 6.0m) |

N2 management |

|

N2 heater | standard equipped |

N2 temp range | 0 - 350 C |

N2 consumption | 1---3m³ /h / nozzle |

Support and Services:

The SMT Selective Wave Soldering Machine is a high-quality and

reliable device designed to solder through-hole components on

printed circuit boards.

Our product technical support team is available to assist you with

any questions or issues you may encounter while using the machine.

Whether it's installation, maintenance, or troubleshooting, we are

committed to providing you with prompt and effective solutions.

In addition to technical support, we also offer a range of services

to ensure the optimal performance of your SMT Wave Soldering

Machine. These services include:

Machine calibration and optimization

Regular preventive maintenance

Upgrades and modifications

Operator training and certification

By choosing our SMT Wave Soldering Machine, you can be confident

that you will receive not only a top-quality product but also

exceptional technical support and services.